Designing with naturally textured stone

By Hiro Kamizono

Designing with stone takes careful consideration of field conditions and collaboration with fabricators to achieve designed alignments and design outcomes. When working with a naturally textured stone, an even greater degree of thought and preparation is needed to develop, fabricate, and realize the design.

The Chalette Residence in Beverly Hills features a basement-level courtyard bringing natural light and fresh air to a space typically devoid of natural connection. A key feature of this courtyard is a wall clad in highly textured stone which animates and enhances the natural feel of the space in a way that typical flat stone slabs would not.

The inconsistent physical properties of the large textured stone posed a challenge in our design. In response, we developed an innovative design process that utilizes 3D scanning and computational design techniques to understand the material characteristics of the stone and to incorporate the constraints of fabrication and installation into a design solution that pushes both the physical limitations and aesthetic boundaries of visualization.

This is an image caption in a 1-column row.

Material: Quarry Face Stone Slabs

The limestone, sourced by Maiden Stone, originates from a Spanish quarry where large raw blocks are carved from a mountain and transported to a factory to be sliced into slabs and tiles. Tiles can then be surface treated to achieve various finishes for different applications including floors, countertops, and walls. At this residence, the same stone is used as the indoor-outdoor flooring throughout the main spaces.

As we further explored stone finishes, we discovered quarry face stone slabs, the standard finish with the heaviest texture. Unlike the split face, the quarry face is not a finish, but rather a thin slice of the untreated natural surface of the raw block. Oftentimes these pieces are disposed of during the tile production process. However, through close communication with the manufacturer, we were able to reserve the quarry stone slabs in roughly 4’x8’ pieces.

Panel Layout: Intentional Mis-registration

Since the texture is a result of the production process, the thickness and surface quality varies greatly within and between slabs which makes it difficult to know how pieces are cut to a manageable size for the installers to align with each other. Once we understood the size constraints, we broke down the wall surface into a panel pattern and incorporated the misregistration between panels as part of the design. Visualizing and controlling the exposure between panels, however, still remained elusive.

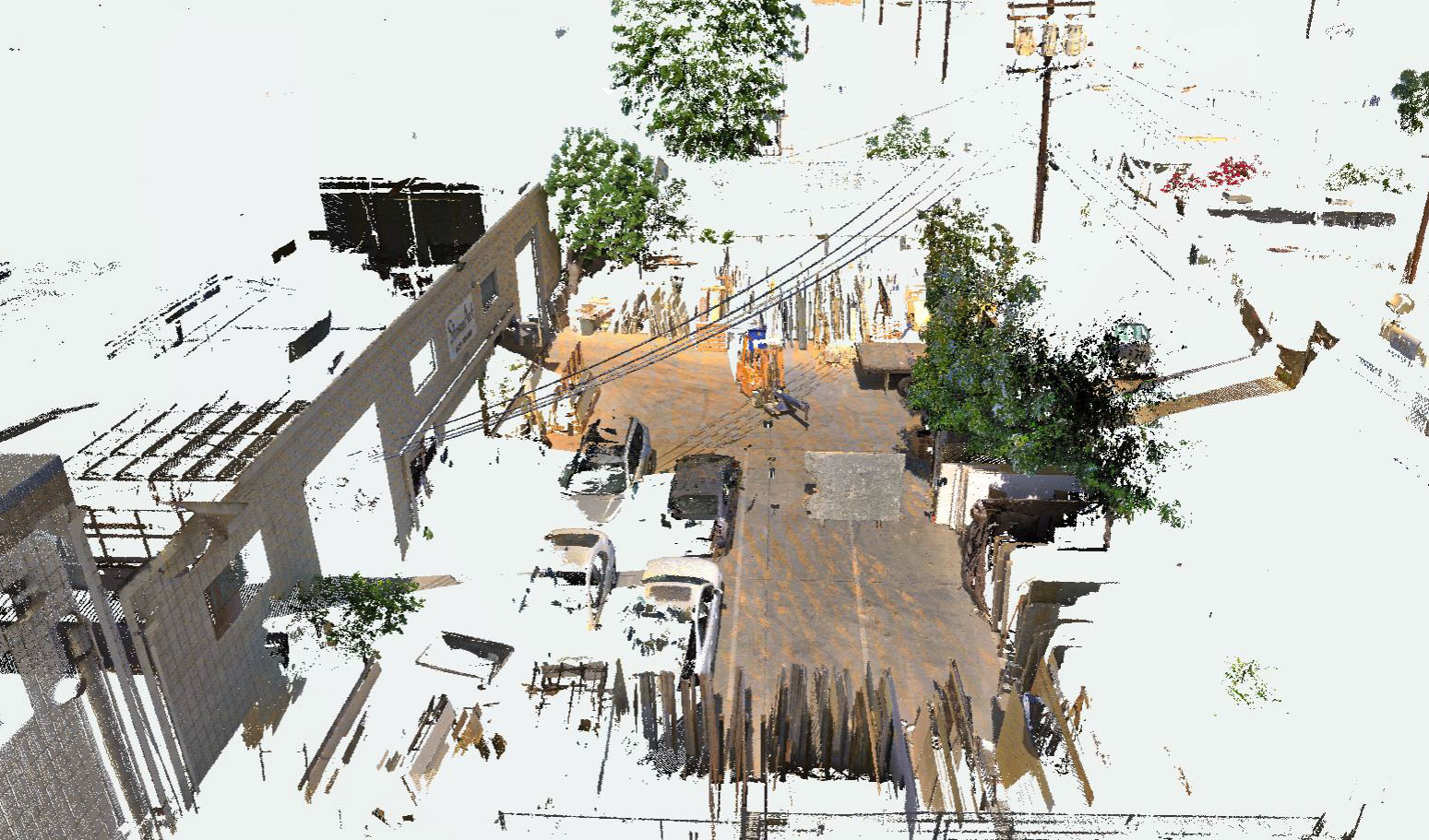

Color & Texture: 3D Scanning

We saw this challenge as a unique opportunity to utilize Faro’s Focus S 3d scanner, a tool typically used to capture large spaces rather than discreet objects, to help us digitally study the final design of the roughly 13’H x 25’W feature wall. At the stone fabricator’s yard, each slab was set against a steel frame and the scanner was carefully placed to capture their color, texture, and thickness. (3D scanner – Focus S by Faro)

Computational Design: Dynamic Updates & Optimization

A key aspect in the design coordination process was engaging computational design to translate the rough scan data to pieces that fit our panel layout. Once the scans were converted to polygon meshes and laid flat on a digital plane, the panels were laid out on specific slabs to avoid undesired blemishes in certain slabs, and to maintain proper edge clearances for the cuts.

Custom scripts were then developed to dynamically update the panel cuts and boundaries on individual slabs and how those manifest on the wall. Thus we were able to study the daylight conditions between adjacent panels and mitigate extreme misregistration and ledges on the wall and waterfall.

The Outcome

Often in the construction process, challenges help us invent new and unexpected solutions. In this case, the resolution was a systematic, technology-driven process that resolved issues of visualization and fabrication coordination that a conventional process could not foresee.

The feature wall at the Chalette Residence is a stunning, multi-dimensional wall that required a streamlined design process and a high-level of detail in order to achieve the final result. The fabrication and installation are currently in process and completion is expected in late Fall of 2019.